China’s new infrastructure includes communication network infrastructure represented by 5G, Internet of Things, Industrial Internet, Industrial Internet of Things and Satellite Internet, new technology infrastructure represented by artificial intelligence, cloud computing, and blockchain, and arithmetic infrastructure represented by data centers and intelligent computing centers.

Convergence infrastructure includes intelligent transportation infrastructure, smart energy infrastructure, etc. Innovation infrastructure includes major science and technology infrastructure, science and education infrastructure, industrial technology innovation infrastructure, etc.

New infrastructure has great potential in fostering new economic dynamics and is favored by all parties. As one of the main representatives of communication network technology facilities, Industrial Internet hits the pain point of transformation of Chinese industrial enterprises and is the cornerstone of digitalization, networking, and the intelligent transformation of Chinese industrial manufacturing.

The new infrastructure has arrived, how will the industrial Internet develop in the future? What kind of opportunities will the Industrial Internet of Things face? Today we will talk about the Industrial Internet and the Industrial Internet of Things.

Industrial Internet and Industrial Internet of Things, the difference between one word, what is the difference?

The difference between Industrial Internet and Industrial Internet of Things is a word, but the contents covered are very different.

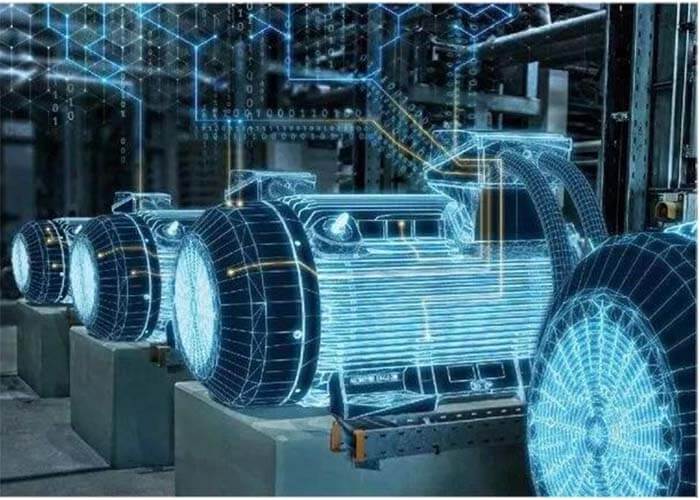

Industrial Internet is not the Internet of industry, but the Internet of industrial interconnection. It is to connect people, data, and machines in the industrial production process, to digitize, automate, intellectualize and network the industrial production process, to realize the flow of data, to improve production efficiency and reduce production costs.

From the perspective of technical architecture, the Industrial Internet includes device layer, network layer, platform layer, software layer, application layer, and overall industrial security system. Compared with the traditional Internet, there is an additional device layer.

- The device layer is responsible for data collection and preliminary calculations to perform production actions.

- The network layer is responsible for the transmission and forwarding of information.

- The platform layer is responsible for the orchestration of infrastructures such as network, storage, and computing.

- The software layer is responsible for the implementation of software for R&D and design, production control, and information management of industrial production processes

- The application layer is responsible for the embodiment of the value of the industrial Internet and the formation of solutions and applications in different verticals and industries.

- The industrial security system is responsible for the security of each industrial production, ranging from the operation and maintenance of equipment replacement, security authentication at the network level, and security vulnerabilities at the platform software level.

The Industrial Internet of Things is the infrastructure in the Industrial Internet, which connects the device layer and the network layer, laying a solid foundation for the platform layer, the software layer, and the application layer. The device layer in turn contains the edge layer. Overall, IoT covers cloud computing, network, edge computing, and terminals, and opens up the key data streams in the Industrial Internet from the bottom up.

Architecturally, IoT is divided into the perception layer, communication layer, platform layer, and application layer.

The perception layer mainly consists of sensors, visual perception, and programmable logic controller (PLC) devices, which collect data such as vibration, temperature, humidity, infrared, ultraviolet, magnetic field, image, acoustic stream, video stream, etc., and transmit them to the network layer to reach the upper management system to help it record, analyze and make decisions, and on the other hand, collect commands issued or already programmed from the upper management system to execute device actions. .

The communication layer mainly consists of various network devices and lines, including optical fiber and xDSL with network fixed lines, but also GPRS, 3G, 4G, 5G, WiFi, ultrasonic, ZigBee, Bluetooth, and other communication methods through radio wave communication, mainly to meet the communication needs of different scenarios.

The platform layer mainly precipitates the data transmitted from the bottom layer after correlation and structured analysis as platform data, connects sensing downward, and provides unified programmable interfaces and service protocols upward, which reduces the design complexity of the upper layer software and improves the coordination efficiency of the overall architecture, especially at the platform level, the precipitated data can be analyzed and mined through big data to provide data for production efficiency, equipment inspection, and another decision making.

The application layer is mainly landed as verticalized application software according to the needs of different industries and fields. By integrating the data precipitated by the platform layer and the control commands configured by users, it realizes efficient application of terminal devices and finally improves production efficiency.

There is a gateway in the middle of the sensing layer and the communication layer. The gateway isolates the terminal sensors and controllers from the upper layer network ports, which reduces the complexity of the business logic of sensors and controllers on the one hand, and reduces the cost of parsing data protocols for upper-layer applications on the other.

Industrial Internet covers the industrial Internet of Things. Industrial Internet is to realize the comprehensive interconnection of people, machines, and things, and the pursuit is digitalization; while Industrial Internet of Things emphasizes the connection of “things to things” and the pursuit is automation. The Industrial Internet of Things is a cross-network system of Internet of Things and Internet, and it is also a breakthrough in the deep integration of automation and informationization.

Within the industrial Internet system, industrial software is the soul and the pivot of the overall control orchestration; industrial IoT takes data as the blood and provides various useful information and nutrients for the industrial Internet.

With the advent of the 5G era, what kind of development will the industrial Internet of Things usher in?

When Industrial Internet of Things meets 5G

5G has the characteristics of large bandwidth, low latency, and wide coverage, which has cracked the network problem of industrial IoT. However, 5G is not a silver bullet at this stage, and there are still many challenges when industrial IoT uses 5G for transformation and upgrading.

Base station construction challenges

5G has been commercialized, but the construction of 5G base stations is not yet completed, 5G signals have not yet covered a large area, and 5G applications are restricted.

Cost challenges

5G phenomenal applications have not yet emerged, which means that the terminal demand for 5G is still at a low-level stage, resulting in low production and high cost of 5G chips and tens of times higher module cost than 4G. When 5G really achieves popularity from base stations to application terminals, industrial IoT will also take a new step in terms of network deployment efficiency.

Standards Challenge

The standard of industrial IoT devices and systems is not uniform, and industrial software needs to coordinate various devices and be compatible with private protocols of different vendors in order to realize automation.

Talent Challenge

The industrial Internet has a long industrial chain, which requires a high level of talent, and China has a relative shortage of talent in this area.

Security Challenges

Cloud computing, especially the public cloud, cannot dispel the security concerns of business owners, and privatization brings the problem of non-standard. These issues are both difficulties and opportunities for entrepreneurs in the development of the Industrial Internet of Things.

Four points of reflection and judgment

In the future, what will be the segments of the industrial Internet of Things?

Industrial gateway

In the 5G era, the industrial gateway will have a higher performance network and become an important infrastructure for edge computing. Image recognition, path planning, pattern recognition, and other localization functions can be solved at the gateway level.

Industrial Internet of Things Security

Network security is a higher level of network requirements. At the network level of industrial IoT, there are several major demands for interoperability, high-performance network, and security network. With the digital transformation of enterprises, the demand for cybersecurity of the industrial Internet of Things will also see explosive growth.

Industrial Intelligent Robots

China has a strong demand for industrial robots, and the current procurement volume is the first in the world, but the density of industrial robots is insufficient, and the independent capability of industrial robot R&D and production is insufficient, and the two deficiencies contain a huge development space.

Network Module

After the popularity of the industrial Internet and industrial Internet of Things, every device and every sensor will need corresponding transmission modules, so the demand for network modules will also see explosive growth.

2021 is destined to be a key year for industrial development. Industrial manufacturing in remote collaboration, cloud management needs urgent, the popularity of industrial Internet and industrial Internet of things will usher in new opportunities.

Besides the Industrial Internet VS Industrial Internet of Things article, You may also be interested in the below articles.

What is the difference between WIFI and WLAN?

Summary of 41 Basic Knowledge of LTE

What Is The 5G Network Slicing?