Microwave Absorbing Foam Absorbing material refers to a type of material that can absorb or greatly reduce the electromagnetic wave energy received on its surface, thereby reducing the interference of electromagnetic waves. In engineering applications, in addition to requiring high absorption of electromagnetic waves in a wide frequency band, the absorbing material is also required to have lightweight, temperature resistance, humidity resistance, and corrosion resistance.

1. What is Microwave Absorbing Foam?

1.1. With the development of modern science and technology, the impact of electromagnetic radiation on the environment is increasing.

At the airport, the flight cannot take off due to electromagnetic wave interference, and it is delayed; at the hospital, mobile phones often interfere with the normal operation of various electronic diagnoses and treatment equipment. Therefore, the treatment of electromagnetic pollution and the search for a material that can withstand and weaken electromagnetic wave radiation-absorbing materials have become major issues in materials science.

1.2. Electromagnetic radiation causes direct and indirect damage to the human body through thermal, non-thermal, and cumulative effects.

Studies have confirmed that ferrite-absorbing materials have the best performance, which has the characteristics of a high absorption frequency band, high absorption rate, and thin matching thickness.

Applying this material to electronic equipment can absorb leaked electromagnetic radiation and achieve the purpose of eliminating electromagnetic interference. According to the law of electromagnetic waves propagating in the medium from low magnetic to high magnetic permeability, high magnetic permeability ferrite is used to guide electromagnetic waves, through resonance, a large amount of radiant energy of electromagnetic waves is absorbed, and then the energy of electromagnetic waves is converted into heat energy through coupling.

1.3. In the design of the absorbing material, two issues should be considered:

1). When the electromagnetic wave encounters the surface of the absorbing material, pass through the surface as much as possible to reduce reflection;

2). When the electromagnetic wave enters the inside of the absorbing material, The energy of electromagnetic waves is lost as much as possible;

2. What is Microwave Absorbing Foam Classification?

2.1. Microwave Absorbing Foam is Classified by the loss mechanism of absorbing materials.

1) Resistive loss

This kind of absorption mechanism is related to the resistive loss of the material’s conductivity, that is, the greater the conductivity, the greater the macro current caused by carriers (including the current caused by the change of electric field and the eddy current caused by the change of magnetic field). Large, which is conducive to the conversion of electromagnetic energy into thermal energy.

2) Dielectric loss

Which is a kind of dielectric loss absorption mechanism related to electrodes, that is, the electromagnetic energy is converted into heat, and the energy consumption is dissipated by the friction caused by repeated polarization of the medium. The dielectric polarization process includes electron cloud displacement polarization, polar dielectric moment turning polarization, electric ferrite domain turning polarization, and wall displacement.

3) Magnetic loss

This type of absorption mechanism is a type of magnetic loss related to the dynamic magnetization process of ferromagnetic media. This type of loss can be refined into hysteresis loss, gyromagnetic eddy current, damping loss, and magnetic aftereffects, etc., Its main source is the magnetic domain turning, magnetic domain wall displacement, and natural resonance of the magnetic domain similar to the hysteresis mechanism. In addition, the latest microwave loss mechanism of nanomaterials is a hot spot in the analysis of absorbing materials today.

2.2 According to the element classification of the absorbing material.

1) Carbon-based absorbing materials, such as graphene, graphite, carbon black, carbon fiber, and carbon nanotubes;

2) Iron-based absorbing materials, such as ferrite, magnetic iron nanomaterials;

3) Ceramic absorbing materials, such as silicon carbide;

4) Other types of materials, such as conductive polymers, chiral materials (left-handed materials), and plasma materials;

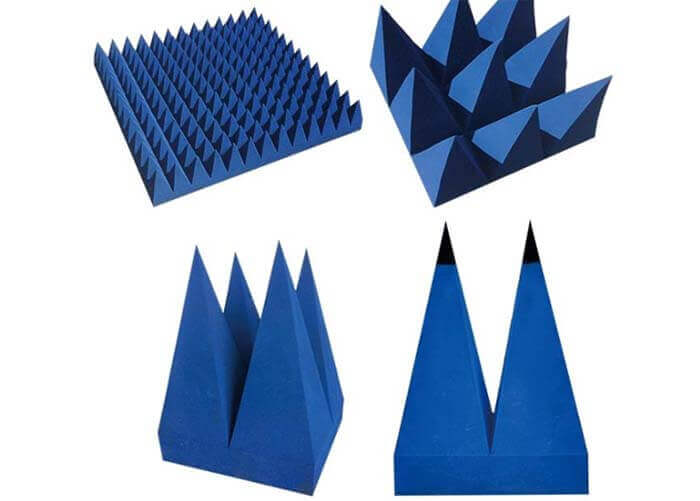

3. Microwave Absorbing Foam’s Shape

3.1 Wedge shape

The absorber used in the microwave anechoic chamber is often made into a wedge shape (RF Absorber Foam Pyramidal), which is mainly composed of polyurethane foam type, non-woven fabric flame-retardant type, and silicate plate metal film assembly type.

As the frequency decreases (wavelength increases), the length of the absorber also increases greatly. The common wedge-shaped absorber has an approximate relationship of L/λ≈1, so at 100MHz, the wedge length reaches 3000mm, which is not only difficult to achieve in the process, And the effective available space of the microwave anechoic chamber is also greatly reduced.

3.2 Single-layer flat shape

The first absorber developed abroad is a single-layer flat plate Radar Absorbing Foam sheet, and the absorber made later is directly attached to the metal shielding layer, which is thin in thickness and light in weight, but has a narrow working frequency range.

3.3 Double or multilayer flat shape

This kind of absorber can work in a wide operating frequency range and can be made into any shape. For example, NEC Corporation of Japan disperses ferrite and short metal fibers evenly in a suitable organic polymer resin to make composite materials, and the working frequency band can be expanded by 40% to 50%. Its disadvantages are large thickness, complicated process, and high cost.

3.4 Coating shape

Only coating-type absorbing materials can be used on the surface of the aircraft, which broaden the frequency band, and generally use composite coatings.

For example, when the thickness of the lithium cadmium ferrite coating is 2.5mm~5mm, it can attenuate 8.5dB in the centimeter band; when the thickness of the spinel ferrite coating is 2.5mm, it can attenuate 24dB at 9GHz; the ferrite is chlorinated When the thickness of the butadiene rubber coating is 1.7mm~2.5mm, the attenuation is about 30dB at 5GHz~10GHz.

3.5 Structural shape

Incorporating absorbing materials into engineering plastics makes them have both absorbing characteristics and load-bearing capacity, which is a direction for the development of absorbing materials.

Nowadays, in order to further improve the performance of absorbent materials, several complex types of absorbent bodies with combinations of shapes have been developed abroad. For example, a microwave anechoic chamber made of this type of absorber in Japan has performances: 136MHz, 25dB; 300MHz, 30dB; 500MHz, 40dB; 1GHz-40GHz, 45dB.

4. What is Microwave Absorbing Foam Engineering application?

In the increasingly important stealth and electromagnetic compatibility (EMC) technology, the role and status of electromagnetic wave absorbing materials are very prominent, and they have become the magic weapon and secret weapon of electronic countermeasures in the modern military. Its engineering applications are mainly in the following aspects.

4.1. Stealth technology

Coating absorbing materials on various weapons and military facilities such as airplanes, missiles, tanks, ships, warehouses, etc. can absorb reconnaissance radio waves and attenuate reflected signals, thereby breaking through enemy radar defenses. This is a kind of anti-radar reconnaissance. A powerful method to reduce the weapon system from being attacked by infrared-guided missiles and laser weapons.

4.2. Improve the EMC performance of the whole machine

The false signals generated by the reflection of electromagnetic waves by the aircraft fuselage may lead to false interception or false tracking of highly sensitive airborne radars; when several radars on an aircraft or a ship are working at the same time, the crosstalk between the radar transmitting and receiving antennas is sometimes very serious, the jammer on the plane or on the ship will also interfere with the radar or communication equipment…

In order to reduce such interference, the excellent magnetic shielding of absorbing materials is commonly used abroad to improve the performance of radar or communication equipment. If the radar or communication equipment fuselage, antenna, and all surrounding interferences are coated with absorbing materials, it can make them more sensitive and accurate to find enemy targets;

Coating the absorbing material on the surrounding wall of the opening of the radar parabolic antenna can reduce the interference of the sidelobe to the main lobe and increase the working distance of the transmitting antenna, and it can reduce the interference of false target reflection on the receiving antenna;

The application of absorbing materials in satellite communication systems will avoid interference between communication lines, improve the sensitivity of satellite-borne communication machines and ground stations, and thereby improve communication quality.

4.3. RFID antenna anti-metal isolation application

This application mainly uses the high track rate characteristics of a type of high magnetic track rate, low loss type absorbing material; when used, insert the wave absorbing plate between the 13.56MHz loop antenna and the metal substrate to increase the induced magnetic field through the wave absorbing material By itself, it reduces the chance of passing through the metal plate, thereby reducing the induced eddy current in the metal plate, thereby reducing the loss of the induced magnetic field.

At the same time, due to the insertion of the absorber, the measured parasitic capacitance will also be reduced, and the frequency deviation will be reduced, which is consistent with the resonant frequency of the reader, thereby improving the reading distance. Of course, the degree of improvement depends on the quality of the absorbing material.

4.4 Security protection

Due to the application of high-power radars, communication devices, microwave heating, and other equipment, preventing electromagnetic radiation or leakage and protecting the health of operators is a new and complex topic. Absorbing materials can achieve this goal. In addition, today’s household appliances generally have electromagnetic radiation problems, which can be effectively suppressed through the rational use of absorbing materials and their components.

4.5. Microwave anechoic chamber

The space formed by the wall surface decorated by the absorber is called a microwave anechoic chamber. An equivalent non-reflective free space (no noise zone) can be formed in the microwave anechoic chamber, and the electromagnetic waves reflected from the surroundings are much smaller than the direct electromagnetic energy and can be ignored.

Microwave anechoic chambers are mainly used for the measurement of characteristic impedance and coupling degree of radar or communication antennas, missiles, airplanes, space crafts, satellites, etc., the measurement of astronauts’ shoulder antenna pattern, and the installation, testing, and adjustment of spacecraft, etc.

It can eliminate external clutter interference and improve measurement accuracy and efficiency (indoors can work around the clock), and it can also keep secrets.

Besides the Microwave Absorbing Foam article, you may also be interested in the below articles.

What is the difference between WIFI and WLAN?

Summary of 41 Basic Knowledge of LTE

What Is The 5G Network Slicing?